LB-Co-extrusion doub kouch wpc pwofil extrusion liy

Materyèl anvan tout koreksyon + pouvwa bwa + aditif → melanje → granulation → konik twin-screw extruder → pwofil extrusion mwazi → fre bòdi mouri → sipò kalibrasyon vakyòm → bwote-off → kouto → etajè → pwodwi fini

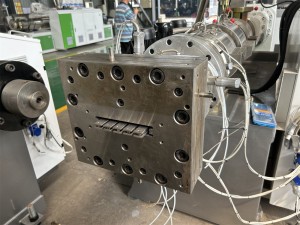

1> konik doub vis extruder: SJSZ-65/132

2> WPC PP / PE / PVC fenèt, pòt, kloti, tabliye, jip, mwazi pwofil etaj

3> Vacuum kalibrasyon sistèm

4> Rale machin

5> Koupe machin

6> bracket egzeyat

7> Panneau

8> Relief machin

| Modèl extruder | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Pouvwa motè (kw) | 22 | 37 | 55 | 110 | ||

| Lajè pwodwi | 200 | 240 | 300 | 600 | 900 | 1200 |

| Pouvwa vakyòm | 4kwX1 | 5.5kwX1 | 5.5kwX1 | 5.5kwX2 | 5.5kwX1 7.5kwX1 | 5.5kwX1 7.5kwX1 |

| ponp dlo | 2.2kw | 2.2kw | 4kw | 5kw | 7.5kw | 7.5kw |

| Transpò vitès | 0-5m / min | 0-5m / min | 0-5m / min | 0-3m / min | 0-2.5m/min | 0-2.5m/min |

| Kapasite (kg/h) | 70kg/h | 110kg/h | 110kg/h | 170kg/h | 300kg/h | 300kg/h |

| Pwa nèt (kg) | 3000 | 5000 | 6500 | |||

Si matyè premyè se PE oswa PP, ou bezwen melanje poud bwa + patikil PP / PE ansanm, epi mete yo nan liy pelletizing, finalman jwenn granules plastik bwa final.